- TOP

- Cutting-edge Research and Social Contribution

- Cutting-edge Research

- Safer flying and better fuel economy: Cooperation with JAXA

Safer flying and better fuel economy: Cooperation with JAXA

Osamu NOZAKI

- Specialized field

Aeropropulsion, gas turbine, turbomachinery, aerodynamics

Cutting-edge aeronautical technology: legacy for the next generation

Prof. Nozaki did cutting edge aeronautical technology research and development at the Japan Aerospace Exploration Agency (JAXA) and before that at the National Aerospace Laboratory of Japan (one of the predecessors of JAXA) for a total of some 30 years. He has contributed significantly to the development of aeronautical technology, including efforts in the latter half of the 1980s to establish simulation technology for supercomputer analysis of air flow inside jet engines.

Prof. Nozaki says, "In those days, analysis by experimentation was the mainstream approach to engine research, and nobody took us seriously--they said they didn't trust the flow calculations. However, we were able to present data that agreed with the experimental results, so we gradually gained credibility. Eventually we were able to make practically accurate predictions with simulations; until then it was not possible without experimentation."

In the meantime, Japanese jet engine manufacturers became interested in simulation technology and actively undertook collaborative research with Prof. Nozaki's team. Simulation technology also helped manufacturers to develop their products, which subsequently led to the improvement of Japanese technical capabilities.

The increase in environmental load (in terms of factors such as noise and exhaust gas) resulting from increased air transport is of great concern, and the development of environmentally friendly aircraft is urgently needed. In his research Prof. Nozaki also contributed significantly to the enhancement of fuel efficiency, particularly by pursuing efficient air flow inside jet engines. In recent years, we are seeing a regional jet developed in Japan, and domestic manufacturers are getting stronger; needless to say, the outcomes of the steady pursuit of basic research conducted by JAXA have been the foundation for those technological advances.

"Since Japan's technological capabilities have been acknowledged worldwide, I feel we have contributed to the enhancement of Japan's international competitiveness in aeronautics. Japanese engine makers are promoting new aeroengines to further expand Japan's share in international joint development."

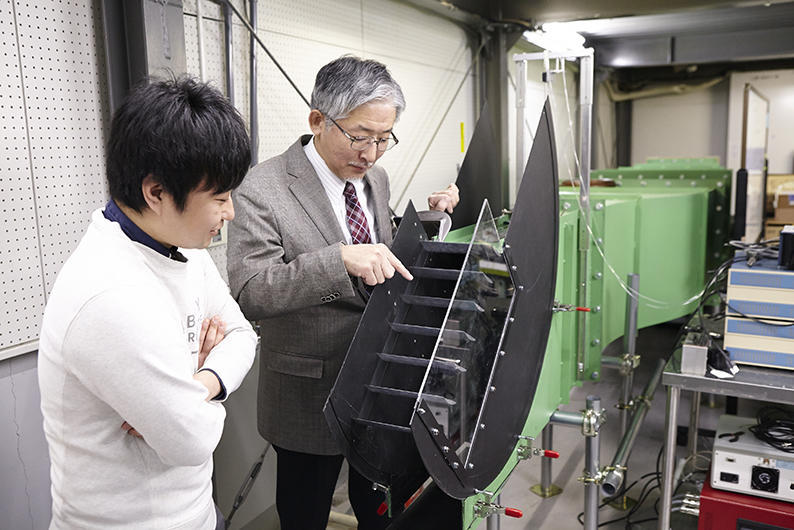

Currently Prof. Nozaki is focusing on research for development towards safe and environmentally friendly next generation aeroengines. Furthermore, as a shortcut to the cultivation of talented human resouces who can play an active part in aviation, he sends his students to work as trainees at JAXA, his old home ground. He says, "I would like to see the experience accumulated in JAXA being incorporated into the education of students who will be responsible for the future of Japan." The students sent to JAXA take part in cutting-edge research together with the researchers there.

Shedding light on the unexplained phenomenon of jet engine icing

One research goal being pursued in collaboration with JAXA is an understanding of jet engine icing. Icing is the phenomenon in which excessively cooled droplets collide with an object and form a layer of ice on the surface of the object. Icing occurs not only on aircraft fuselages but also in jet engines, especially in the compressors and fans that are located in front of the combustor. When icing occurs on an engine, the airflow passage becomes narrow; this impairs aerodynamic performance, and if the ice comes loose it can damage the engine core and the body of the aircraft, which could in the worst case scenario cause the engine to stop. Since many aspects of the icing phenomenon are not understood, and since quantitative data is scarce, Prof. Nozaki and his team have been working to elucidate the phenomenon, initially by gathering icing data.

In a recent experiment, droplets were sprayed onto a model from a nozzle installed inside a refrigerator. This made the model icy, and the amount of ice was measured by means of a non-contact method using equipment including laser displacement meters. Differences in the degree of icing and ice shape have been identified under test conditions, such as droplet size, flow rate and model shape.

Prof. Nozaki explains, "In conventional contact measurement such as measuring the thickness of the surface ice layer with a ruler, there were a number of problems including collapsing shapes and excessive measurement time. One of our objectives is to conduct experiments to develop a non-contact measurement system for the solving such problems."

Constructing a non-contact system for the measurement of icing volume and shortening measurement time will make it possible to measure icing in a state closer to the actual condition, and to measure icing amount on rotor blades with complicated shapes.

Prof. Nozaki continues, "With our experimental results and analyses so far, we are getting to understand the mechanism of ice adhesion and the way the adhesion location shifts when we alter the rotation speed of the fan at the head of the jet engine. To improve the accuracy of the measurement, we are going to conduct icing experiments with ducted fans, which are similar in shape to the fans in aircraft engines."

"Clarifying the mechanism of jet engine icing will enable the development of convenient and efficient technology for protection against icing, and the design of high-performance compressors and fans that reduce icing. As a result, fuel efficiency and safety will be improved and many people will feel more comfortable about flying."

Developing rotor blades for highly efficient rotary wing drones

Another area of research that Prof. Nozaki has been conducting with JAXA is the development of rotor blades for efficient rotary wing drones. While rotary wing drones are widely used, mainly in the fields of observation, photographing and transportation, they do have some disadvantages. They are difficult to drive for long periods of time; and their flight time and range are short, since their rotors must rotate constantly, which consumes a lot of power. Moreover, no method has been developed yet for designing efficient rotor blades for drones. This is the team's current task.

"There has not been enough aerodynamic research on drones yet. A knowledge of aerodynamics is essential for the design of drone wings. In particular, rotary wing drones fly by creating a vortex from the tips of their rotating wings, but when they hover in the air, the vortex moves downward and accumulates, unlike the case of a propeller aircraft, whose vortex flows behind it since it moves forward. Rotor blades for drones need to be designed with consideration of that vortex phenomenon."

To that end, Prof. Nozaki and his team are trying to determine an estimation formula for wing tip vortex position; that formula is necessary for the design of high efficiency rotors. If this research advances successfully, it will be possible to develop rotary wing drones capable of long distances and high speeds, so drones will be usable in other fields as well.

Safety and reliability are indispensable in aviation. It takes an extremely long time before research results can be put into practical use. With the future in mind, Professor Nozaki is conducting basic research with his students and at the same time ensuring that they will develop into human resources who will contribute greatly to the aviation field in Japan.