- TOP

- Cutting-edge Research and Social Contribution

- Cutting-edge Research

- Supplying power to and communicating with body surface sensors via 2D communication through clothing!

Supplying power to and communicating with body surface sensors via 2D communication through clothing!

NODA Akihito

- Specialized field

Microwave engineering, Radio frequency circuits, Wireless communications, Wireless power transfer

2D communication for power supply and communication, using clothing itself as the transmission line

Centralized wearable devices like smartwatches and smartglasses employ wireless communication via radio waves, with a battery as the power source. For distributed wearable systems, however, this sort of configuration is not realistic.

To solve these problems, Dr. Noda's design supplies power to and communicates with elements, without using a battery or antenna, by employing clothing made from conductive fibers as a two-dimensional (2D) transmission line.

Data is also transmitted via the same transmission line, and radio waves for communication are not emitted to the outside. Thus, 2D communication has features not found in ordinary wired/wireless connection methods.

Realizing a network with a high degree of freedom while avoiding issues specific to flexible materials

Extensive R&D has already been done in technical fields where electronic circuits are formed on flexible materials, such as clothing, fabrics, and films. In conventional approaches, numerous individual signal lines are formed on clothing. With the 2D communication that Dr. Noda is working on, on the other hand, the entire garment is used as a single transmission line. Dr. Noda highlights an issue in previous research, "If we make a circuit in the same way as with an ordinary hard circuit board, just replacing the board with a soft material, a new problem appears. Since the material is fabric, short-circuit faults may occur due to the fabric folding or wrinkling, or due to the formation of electrically conductive fuzz."

There are other advantages to avoiding individual wiring and connecting everything in parallel with a uniform material. "Fabric is made through a standardized process of weaving or knitting, so it can be mass produced in rolls. We can make pants or jackets, or long sleeves or short sleeves, all from the same fabric. Also, finished clothing can be freely modified, by changing the mounting location of electronic circuits, or adding and removing circuits."

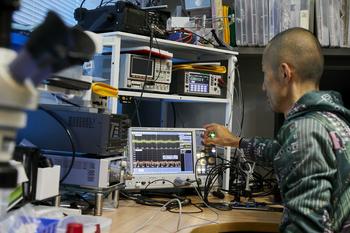

However, since the same transmission line is used for both power supply and data transmission, a system of multiplex transmission is needed. In Dr. Noda's research, continuous DC power supply and data communication are performed simultaneously through a technology called frequency division multiplexing (FDM).

Dr. Noda has also developed new circuit techniques to provide compatibility with existing serial communication methods through the addition of a few electronic circuits. Compatibility with widely-used, existing communication systems allows as-is use of things like commercially-available sensor ICs, which is advantageous for using sophisticated functions built into ICs and existing communication software libraries.

High expectations for applications to health management and preventive medicine, and for boosting growth of the VR industry

The wearable networks that are the focus of Dr. Noda's R&D can simultaneously supply power to and communicate with sensors on clothing, so there is excellent potential for industrial applications, and high expectations in areas like health management and preventive medicine.

This is not a subjective indicator like fatigue or an indirect indicator like working hours. Health management can be done based on objective, direct numeric values, for a safer and more secure work environment. The technology can also support home healthcare for the elderly, and capture detailed body data, so we are also likely to see applications to sports science, and to systems for handling full-body tactile sensation in VR.

Dr. Noda: "In developing such applied systems for solving social problems and creating new industries, there will need to be a lot of trial and error, and I'm looking forward to doing that in earnest with the students at Kochi University of Technology, where I assumed my current position last year." To enable his students to conduct research freely, Dr. Noda wants to establish an environment which is as free as possible from constraints, and focused on creative work.

When asked about what attracts him to his research, Dr. Noda says: "It's the sense of achievement. I notice something--'hmm, maybe it's possible if I proceed this way'--then I verify it with my knowledge, and voila! it works."

While producing research results to meet social and industrial needs in areas like medicine and VR, Dr. Noda will continue working to establish his idea, and highlight the potential for a new paradigm in the field of electronics.

Date of posting: November, 2023/ Date of interview: November, 2022